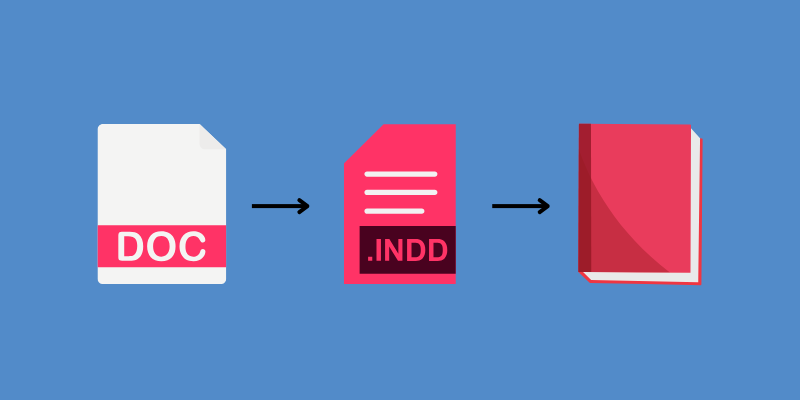

Books at Ooligan take a wonderful journey as an author writes, editors edit, and publishers publish. Throughout it all, there is a design lead (that’s me!) who is making sure that the Word document turns into a tangible book that you get to hold. This is the process of turning that digital file into a ready-for-print file here at Ooligan.

Step 1: Style map it!

The first step is getting the manuscript ready. After an author sends an edited manuscript to the editorial staff here at Ooligan, the Word document is then style mapped. This makes sure that everything that has a specific paragraph style is in the right place. Are the inner monologue thoughts italicized? Style map it. Did we make sure that there is a paragraph break between these two sections? Yes, because we style mapped it.

Step 2: Design it!

Once that is all done, the editors send the Word document to the design team, who turn the document into the pretty and polished file that looks like a real book. An Ooligan designer will transfer the Word document into Adobe InDesign, allowing the text to flow over facing pages. With the style mapping keeping things in place, the designer is able to go through and find chapter titles, stylized body text, and other places that need special formatting. Paragraph styles are applied as the body text is made legible. At Ooligan, we like to keep the size between ten and eleven points, hopefully leading to a total count of 350-400 words per page. This maximizes the space on the page while still allowing for legibility. The designer goes through rounds of feedback to ensure that the font choice for the body text looks perfect, as well as choices for chapter titles and folios.

Step 3: Proofread it!

Once the head publisher sends approval, the designed InDesign file is sent back to the editorial department for a proofread. Students volunteer to compare sections of the designed document to the original Word document. This ensures that nothing was left out or added in during the transfer process. Once that is accomplished, the file is sent back to the design department for printer preparation.

Step 4: Print it!

Ooligan works with two specific printers, Versa Press and Kingery Printing. Depending on the trim size of the book and any treatments to the cover such as a spot gloss or foil, we go with one of the two printers. After setting up a file delivery date and a shipment date, the design lead will set up the final files as PDFs that are ready to be printed. These are reviewed by the head publisher once more, and once proofs are reviewed, we wait eagerly for books to be delivered to the office!

Step 5: Hold, sniff, and admire!

I have discovered that the process of turning the initial Word document into a physical book is such a complex but satisfying process. Along the way, there can be so many technical difficulties, which seems preposterous considering that your final goal is a physical book. But, as I learn to rely on leads and project managers for help, the process is made so much more enjoyable. When I get to go to the office and flip through a book that I helped produce (and even take a sniff of that new book smell), I cannot help but feel proud of the work that we all accomplished.

Written by Ariana Protsman.